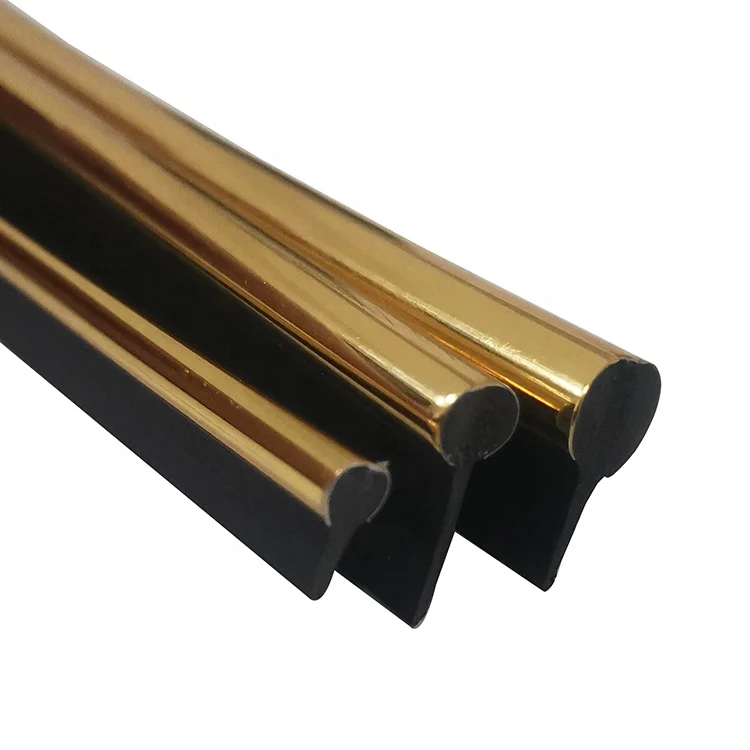

In conclusion, trim materials are an integral component of manufacturing in China, influencing product quality, consumer satisfaction, and overall market competitiveness. As the manufacturing landscape continues to evolve with technological advancements and changing consumer preferences, the role of trim materials will only grow in importance, paving the way for innovative solutions that address both functionality and sustainability. Manufacturers that prioritize high-quality, aesthetically pleasing, and sustainable trim materials will undoubtedly find success in the ever-competitive global market.

Home

Home

They increase the cohesion of the mix, reduce water demand, and improve the open-time, thereby enhancing the overall performance and durability of the final product They increase the cohesion of the mix, reduce water demand, and improve the open-time, thereby enhancing the overall performance and durability of the final product

They increase the cohesion of the mix, reduce water demand, and improve the open-time, thereby enhancing the overall performance and durability of the final product They increase the cohesion of the mix, reduce water demand, and improve the open-time, thereby enhancing the overall performance and durability of the final product This helps to maintain a uniform distribution of the drug throughout the medium, which is essential for achieving consistent bioavailability This helps to maintain a uniform distribution of the drug throughout the medium, which is essential for achieving consistent bioavailability

This helps to maintain a uniform distribution of the drug throughout the medium, which is essential for achieving consistent bioavailability This helps to maintain a uniform distribution of the drug throughout the medium, which is essential for achieving consistent bioavailability